Understanding Electrostatic Discharge (ESD) Origins

ESD primarily occurs through two mechanisms:

Conduction: Charge transfer happens when conductive materials contact charged objects, as electrons flow freely across conductive surfaces.

Friction: Contact and separation of dissimilar materials generates triboelectric charging.

The Critical Need for ESD Control

While conduction and friction are virtually unavoidable, ESD poses serious risks:

• Premature failure of sensitive electronics

• Ignition of flammable substances

• Operational disruptions in critical environments

Litong Anti-Static Color Coated Aluminum Coil: Engineered Protection

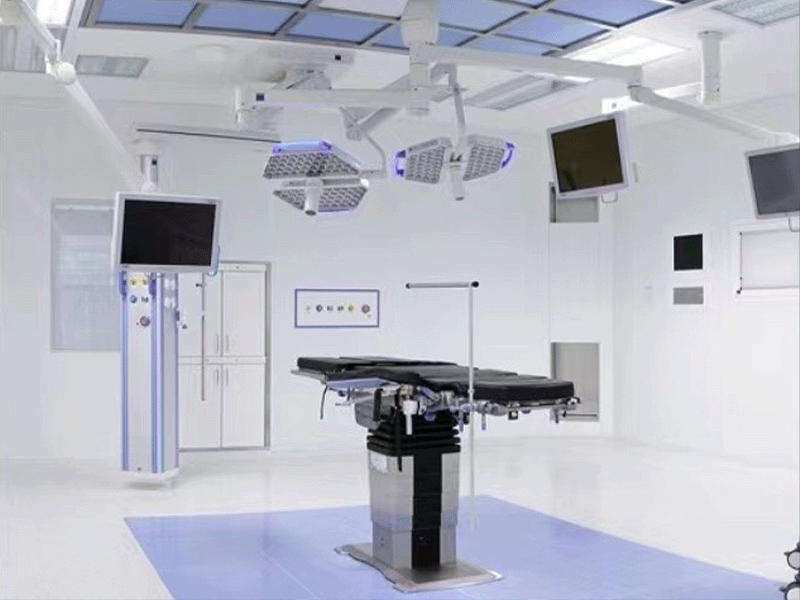

Litong Aluminum's anti-static color coated aluminum coil is suitable for indoor environments with high requirements for dust-free, sterile, and anti-static properties.

Through precision roll-coating technology, we:

• Integrate conductive additives into specialty coatings

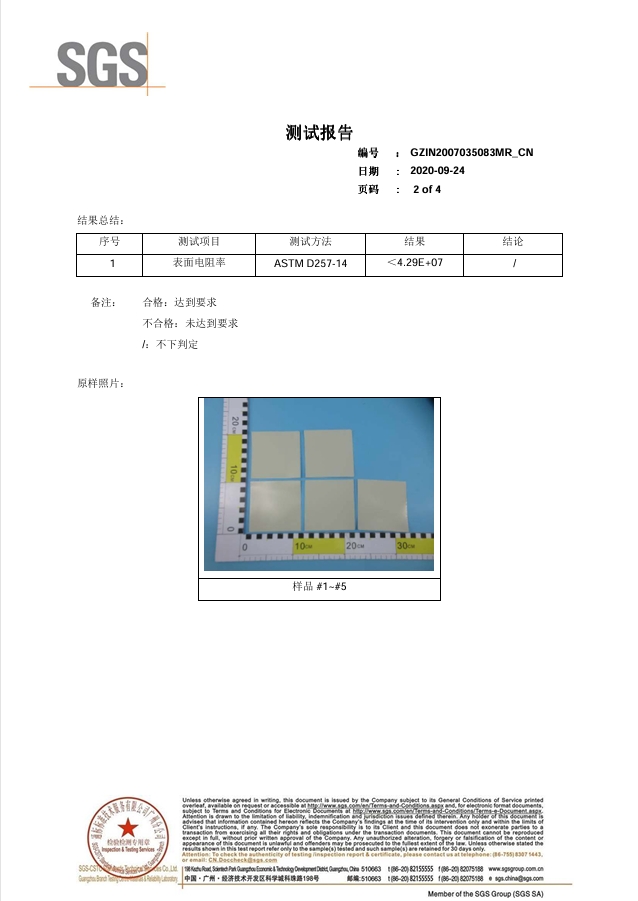

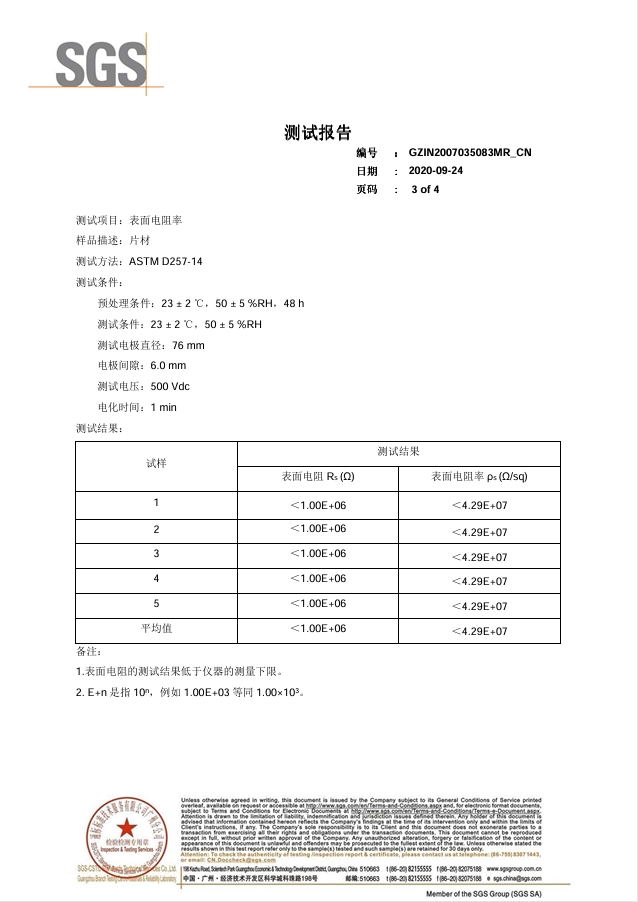

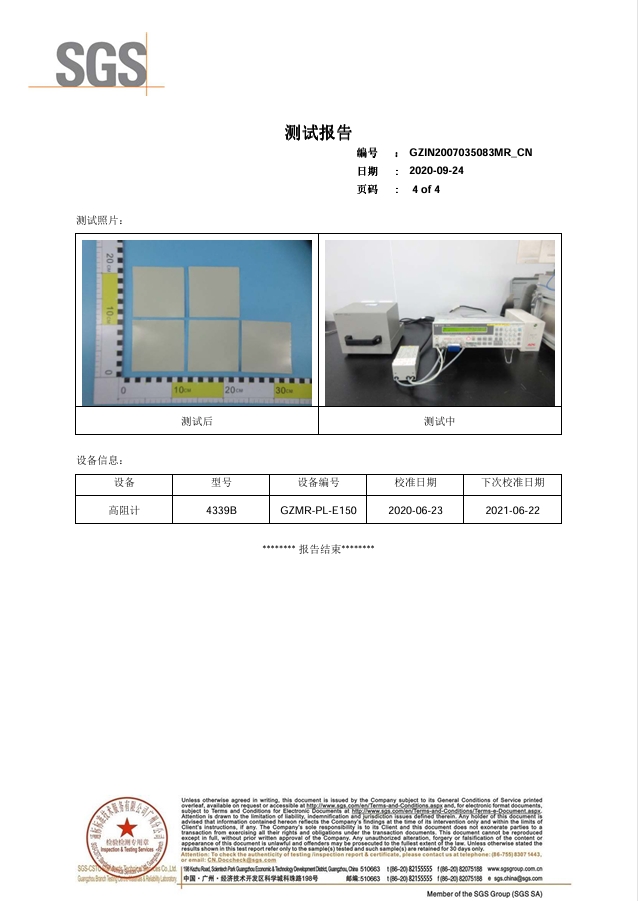

• Achieve surface resistivity of 10⁶–10⁹ Ω (ASTM D257 verified)

• Enable perfect static dissipation through grounding systems

In addition to excellent anti-static properties, anti-static color coated aluminum coils also have excellent adhesion, good corrosion resistance, as well as excellent flexibility and processability.

#Parameter Specification

Alloy: Suitable for various types of aluminum alloys

Substrate thickness: 0.15~1.5mm

Substrate width: within 1600mm, can be divided into strips according to customer needs

Film thickness: Single coating 20 ± 2 microns

#Application scenarios

• Semiconductor fabrication • Electronics manufacturing

• Telecommunications • Precision instrumentation

• Data centers • Pharmaceutical/Biotech facilities

• Medical operating rooms • Textile production

Litong's coated aluminum coils can also provide different functions beyond anti-static. Contact us to explore the infinite possibilities of color coated aluminum coil decoration engineering solutions.