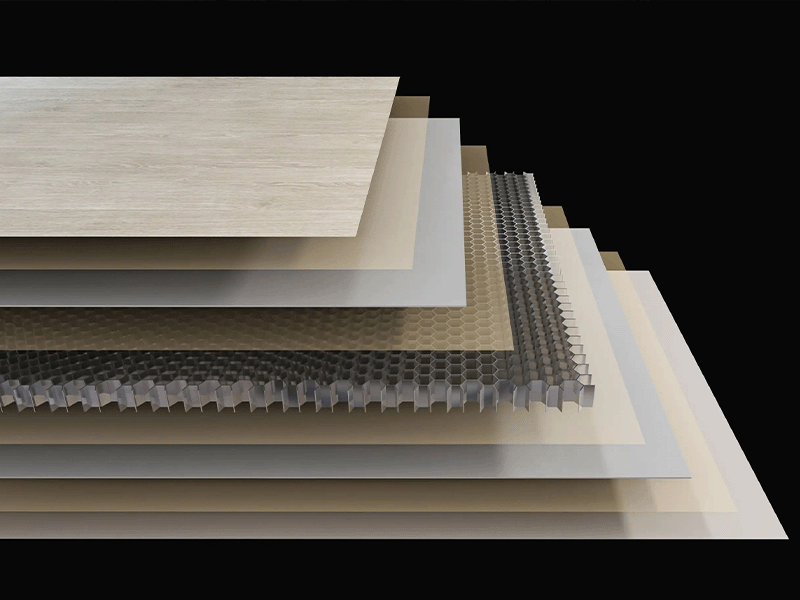

In the field of building curtain walls, aluminum honeycomb panels have become the "favorite" of many large-scale construction projects due to their advantages such as high and flat surface, lightweight material, strong load-bearing capacity, and customization according to needs. Today, let's explore the secrets behind its outstanding performance in the field of architectural curtain walls.

Super weather resistance, unshakable by time

Building curtain walls are exposed to harsh weather conditions such as wind, sun, rain, frost, etc. for a long time, which severely tests the weather resistance of materials.

The aluminum honeycomb panel substrate color coated aluminum coil provided by Litong Aluminum Industry adopts an advanced three roll two coating production process, which evenly rolls fluorocarbon paints with outstanding weather resistance, such as PVDF and FEVE fluorocarbon coatings, onto the surface of the aluminum coil, and then solidifies through high-temperature baking. In this way, the coating film is tightly adhered to the aluminum coil, with strong adhesion. It can not only effectively resist the ruthless irradiation of ultraviolet rays, but also easily cope with the erosion of corrosive substances such as acid rain and salt spray, truly achieving non fading and non powdering.

After professional testing, the weather resistance of Litong Aluminum Aluminum Honeycomb Panel can reach more than 20 years. The building curtain wall can always maintain its original bright color and perfect appearance, enduring the test of time and not afraid of the test of time.

The choice of convenient installation and efficient construction

The installation of large aluminum honeycomb panels is convenient and efficient, bringing unprecedented convenience experience to the construction team.

During installation, aluminum honeycomb panels can be operated in any order, and each wall panel can be independently disassembled and replaced, greatly improving the flexibility during installation and maintenance. At the same time, the aluminum honeycomb panel abandons the traditional welding and nail fixing methods, and adopts corner codes and screw connections, which not only eliminates the tedious processes and safety hazards caused by skeleton welding, but also makes the installation process simpler and faster.

This convenient installation method significantly shortens the construction period, reduces labor costs, and provides strong support for the smooth progress of building curtain wall projects.

Soundproofing and insulation, creators of comfortable spaces

Aluminum honeycomb panels also perform well in sound insulation and heat insulation. The honeycomb core inside the aluminum honeycomb composite panel is cleverly divided into numerous enclosed chambers, which effectively prevent the flow of air and greatly hinder the propagation of heat and sound waves. Aluminum honeycomb panel curtain wall can effectively isolate external noise and reduce the exchange of indoor and outdoor heat, creating a quiet, peaceful, warm and comfortable space indoors.

Whether in hot summer or cold winter, aluminum honeycomb panel curtain walls can maintain a comfortable and pleasant temperature indoors, allowing people to fully enjoy a peaceful and comfortable living and working space.

Aluminum honeycomb panels are undoubtedly the ideal choice in the field of building curtain walls due to their superior weather resistance, lightweight and high-strength characteristics, convenient and efficient installation methods, and excellent sound and heat insulation performance. If you are preparing for an outdoor curtain wall project in construction engineering, Litong Aluminum's honeycomb panel substrate color coated aluminum coil is undoubtedly your best choice.