In traditional decoration, exterior walls and interior materials often compete on their own due to different performance requirements: exterior walls need to withstand wind and sun exposure, while interior walls need to balance environmental protection and aesthetics. The aluminum cone core board can break this boundary, and the core behind it is the color coated aluminum coil.

Litong Aluminum's color coated aluminum coils, with excellent roller coating technology and material characteristics, enable the aluminum cone core board to achieve multiple uses of one material, seamlessly connecting from building facades to indoor spaces, providing a "core" choice for engineering construction projects and interior decoration design.

01 Pain points in indoor and outdoor decoration: precise breaking of color coated aluminum coils

In traditional decoration, exterior wall materials have strong weather resistance but single decorative properties, while interior materials have high aesthetic value but cannot withstand outdoor tests. And the aluminum cone core board substrate color coated aluminum coil directly hits these pain points through the multi energy characteristics of one material:

Performance compatibility: The same substrate color coated aluminum coil can be treated with different coatings (such as outdoor fluorocarbon coating, indoor skin feel/scratch resistance/imitation wood grain stone pattern coating), which can meet the weather resistance requirements of exterior walls for more than 20 years, and also adapt to indoor environmental protection and easy cleaning standards. It can be used in both "exterior wall indoor" places.

Processing flexibility: The color coated aluminum coil can be bent, cut, and punched, easily adapting to complex styling requirements such as curved walls and irregular ceilings, allowing the aluminum cone core board to freely shape in various spaces.

Environmental protection throughout the entire chain: from aluminum coil substrate to surface coating, all have passed international SGS certification, with VOC content far below the national standard. After installation, the aluminum cone core board made from it has better indoor air quality than the national standard, making environmental protection controllable from the source.

02 High end project verification: the all-around performance of color coated aluminum coils

The aluminum cone core board substrate color coated aluminum coil used for the outdoor curtain wall of Yinchuan Workers' Cultural Palace is treated with fluorocarbon coating on the surface, and combined with the addition of scratch resistant materials, the surface hardness of the coating increases. The weather resistance test exceeds 5000 hours, effectively resisting gravel erosion and ultraviolet aging, and maintaining the smooth and new appearance of the curtain wall for a long time.

In response to the high frequency of passenger flow and high hygiene standards at the airport, the interior walls of Yinchuan Hedong International Airport are made of aluminum cone core board substrate color coated aluminum coils. This color coated aluminum coil is easy to clean, and water stains and dirt are difficult to adhere to. Stains can be wiped clean immediately. At the same time, the aluminum cone core board reduces the weight of the board through structural optimization and lightweight design, creating a safe and convenient waiting environment for passengers.

At Guangzhou Liwan Restaurant, which integrates Lingnan architectural style, this aluminum cone core board substrate is coated with color coated aluminum coils, using a brushed texture coating. High precision texture roller coating is completed in the factory, and on-site modular installation avoids secondary processing losses, reduces construction pollution, and shortens the construction period.

03 Technical analysis: Color coated aluminum coils make textures appear fake and indistinguishable from reality

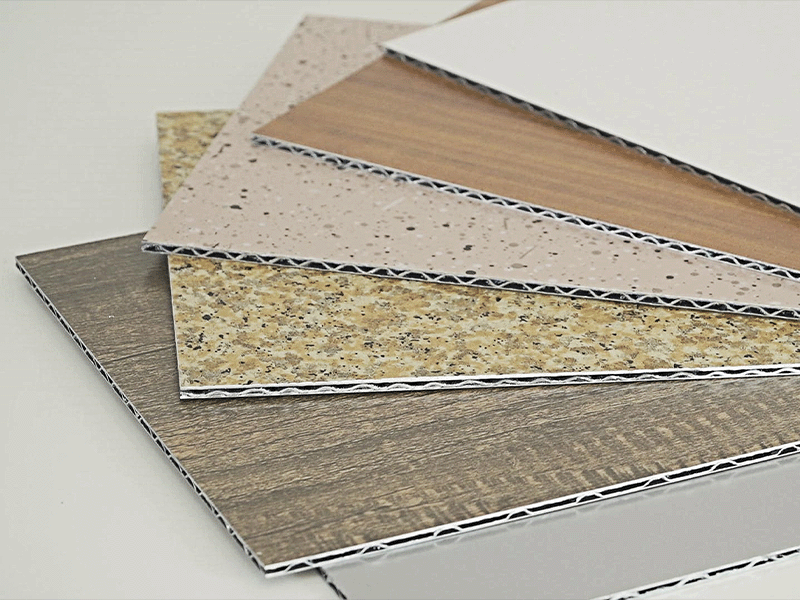

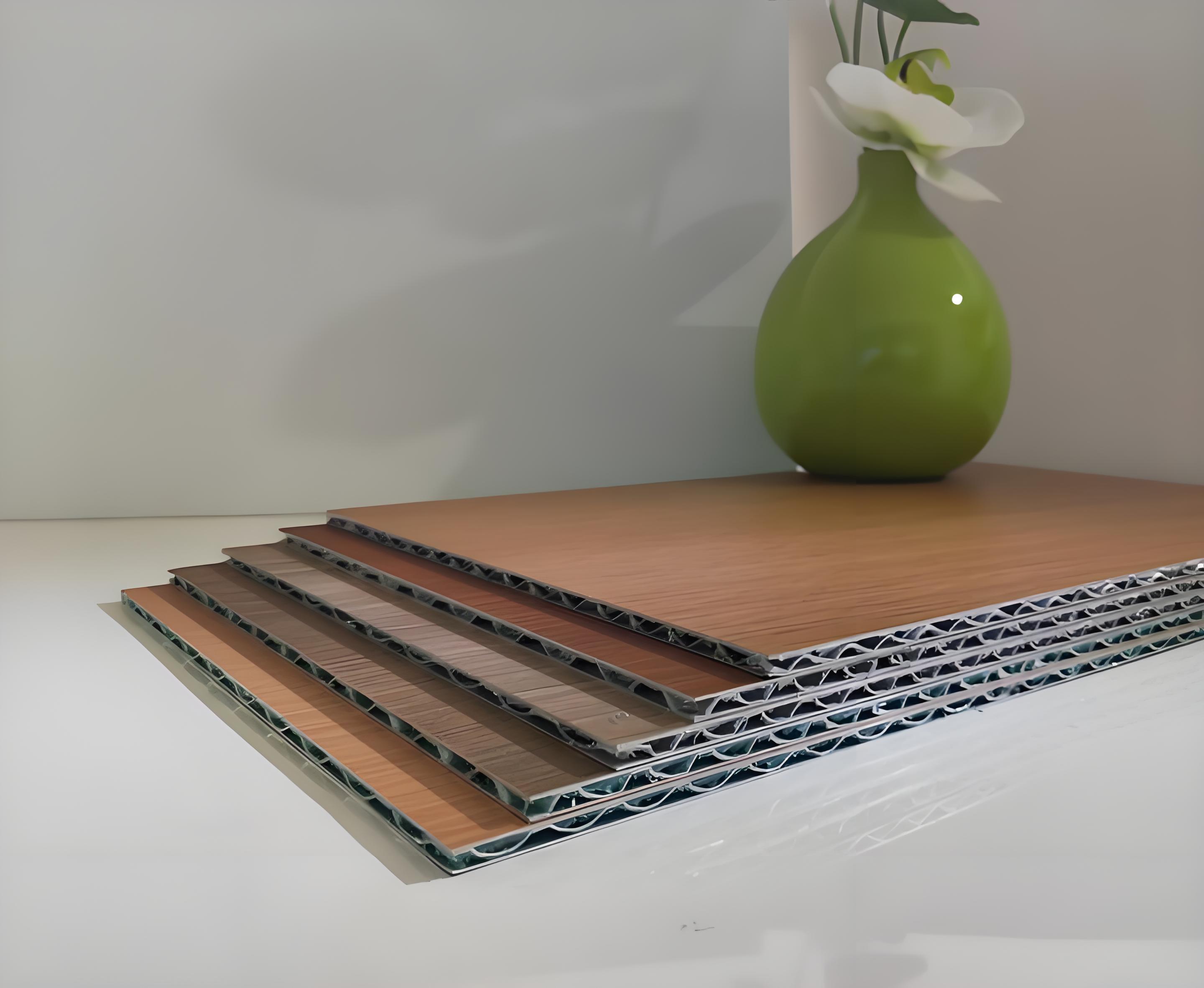

The wood and stone patterns on the surface of the color coated aluminum coil with aluminum cone core board substrate are indistinguishable from reality, perfectly meeting the needs of indoor decoration materials:

Pre roll coating process: By high-temperature and high-pressure roll coating, wood grain and stone grain paint are combined with the molecular level of the aluminum coil surface to form a wear-resistant coating, ensuring that the texture does not peel off or fade.

3D stereoscopic texture technology: Using precision roller coating equipment, a 0.5mm deep concave convex texture is roller coated on the surface of the aluminum coil, with a tactile sensation no different from natural wood and stone, and a clear and realistic wood grain pattern visually.

Full color customization: supports any color number adjustment of Ra ú l and Pantone color cards, and ensures a color difference of ≤ 1.0 through a computer color matching system, allowing the aluminum cone core board to perfectly blend into different spatial color tones.

Guangdong Litong Aluminum Industry's color coated aluminum coils, with exquisite craftsmanship, are widely used as substrates for various metal composite panels in outdoor curtain walls and indoor decoration. Whether it's building exteriors that resist wind and rain erosion, or interior decorations that pursue texture, from iconic facades of high-end hotels and art galleries to exquisite details of furniture countertops and customized cabinet doors, color coated aluminum coils always empower spaces with stable performance and aesthetic value.