In the field of modern architectural decoration, aluminum cone core panels stand out among many building materials due to their unique arch bridge structure and excellent compressive performance, becoming one of the choices for building curtain walls, indoor ceilings, decoration and other scenes.

Aluminum cone core board: Strength and appearance coexist

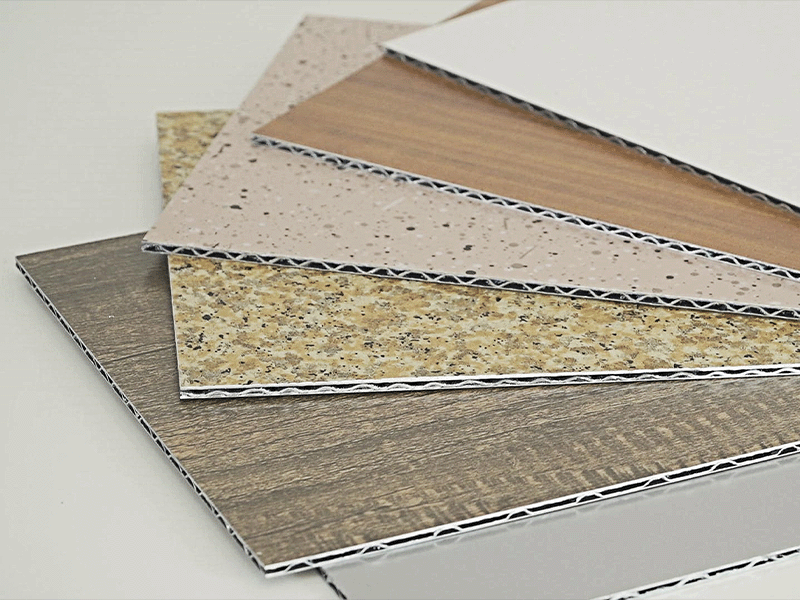

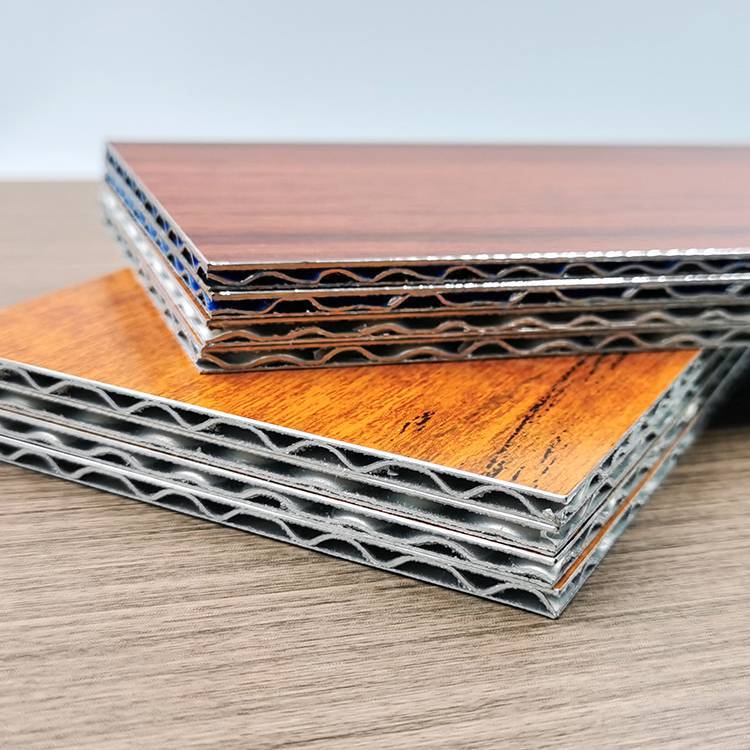

Aluminum cone core plate is a composite metal plate composed of two layers of coated aluminum plates and a conical core material in the middle. This special structure gives it many advantages:

Outstanding appearance: With good flatness and glossiness, it can bring a simple and atmospheric visual effect to the building, enhancing the overall texture.

Superior performance: It has good waterproof and fireproof properties, and can maintain stability even in humid environments or fire hazards; Anti impact pressure, capable of withstanding certain external impacts without being easily damaged; At the same time, it has strong weather resistance and can adapt to different climatic conditions.

With these advantages, aluminum cone core panels are widely used in building curtain walls, indoor ceilings, interior decoration, and interior and exterior wall decoration of large-scale projects, adding unique charm to various types of buildings.

Two crafts, two styles

Aluminum cone core panels that can be used for outdoor curtain walls are mainly produced through two processes: anodizing and pre roll coating, each with its own characteristics and suitable for different demand scenarios.

Anodizing process: a defender of metallic texture

Aluminum plates produced by anodizing process have relatively few color choices and are mostly in their natural metallic color, such as silver white, bronze, etc. But its metallic texture is extremely strong, showcasing a pure and heavy industrial style and modernity, making it very suitable for architectural designs that pursue simplicity, grandeur, and metallic charm.

Moreover, the oxide film formed by the anodizing process is closely integrated with the aluminum plate itself, with good stability, making the aluminum plate have a long service life and can maintain stable performance in outdoor environments for a long time.

Pre roll coating process: an innovator in color and functionality

Unlike anodizing process, pre roll coating process adopts advanced roll coating production line, which endows aluminum plates with extremely rich color choices through precise coating ratio and multi-layer coating technology. This process can achieve precise color matching of any color based on international standard color cards. Not only that, it can also achieve special texture effects such as imitation wood grain and imitation stone grain, giving aluminum plates the texture of natural materials and bringing more possibilities for architectural decoration.

The outdoor curtain wall panels need to use fluorocarbon paint, which can endow the aluminum panels with excellent outdoor weather resistance and effectively resist the erosion of natural environments such as wind, sun, and rain. The tolerance can reach more than 20 years.

Litong Aluminum Industry adopts advanced three roll two coating production technology, producing color coated aluminum coils with excellent quality and diverse performance. These color coated aluminum coils can not only be used for aluminum cone core panels, but also widely used in substrates such as honeycomb panels, aluminum-plastic panels, corrugated panels, etc., providing solid quality assurance for various composite panels.

If you are looking for high-quality color coated aluminum coils, why not choose Litong Aluminum Industry as the source factory, and let high-quality materials help your construction projects!